MHP SpeedF – BESTseller

WSZECHSTRONNA MASZYNA

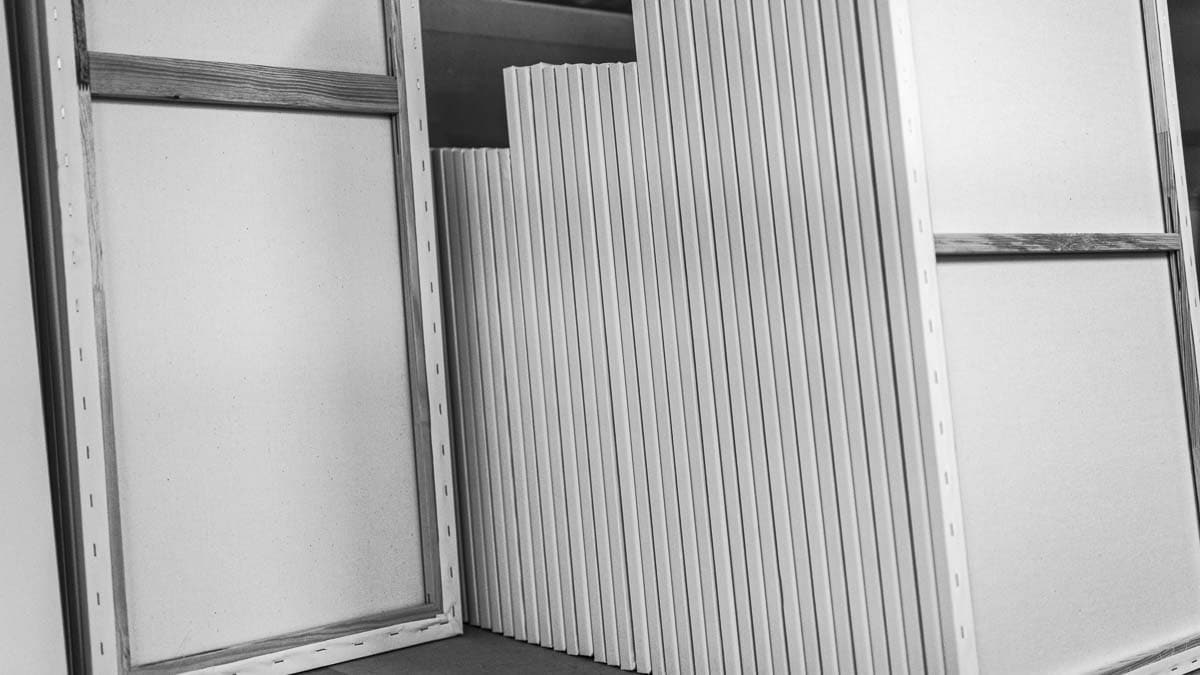

MHP SpeedF jest Państwa najelastyczniejszym rozwiązaniem dla naciągania płótna na ramy w małych i dużych formatach. Półautomatyczna maszyna MHP SF produkuje w dwóch etapach i naciąga każdorazowo dwie strony jednocześnie.

MHP SF, nazywana początkowo SpeedFramer, oferuje Państwu nadzwyczajną elastyczność przy częstych zmianach formatu i szeroki asortyment produkcji. Maszyna ta dba o najwyższą wydajność w pojedynczych produkcjach oraz dużych seriach produkcyjnych dzięki bardzo szybkiej produkcji wielu ram jednocześnie. Posiada ona bardzo duży magazyn zszywek i zapewnia napięcie tkanin takie jak w bębnach oraz najwyższą jakość.

Dla uzupełnienia Państwa produkcji ram polecamy MHP PLUG.

Idealnym rozwiązaniem dla płócien z nadrukami jest MHP VPLUG.

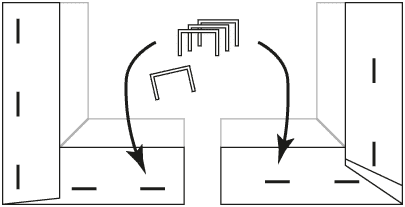

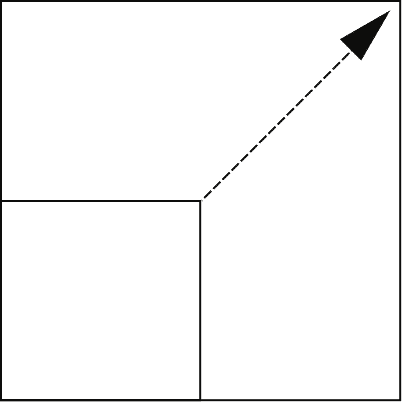

Sposób funkcjonowania

Rodzaj zszywek i zagięcia rogów można dowolnie dopasować

Wydajność

Do 220 ram na godzinę

Formaty

Możliwość ciągłych zmian formatu ram

od 20 x 20 cm do 160 x 160 cm

HIGHLIGHTS

- Do 220 ram na godzinę

- Formaty od 20 x 20 cm do 160 x 160 cm

- Możliwość zmiany formatu w ciągu kilku sekund

- Łatwa, półautomatyczna obsługa

- Multiframe – przygotowywanie wielu ram jednocześnie

- Najnowocześniejsze staplery

- Nowoczesny wyświetlacz dla łatwej obsługi

- Opcjonalna zmiana wysokości

- Napięcie tkanin takie jak w bębnach

- Perfekcyjna jakość dla artystów

- Produkcja 23/7

- z serwisowaniem MH&P

Multilength

Produkcja ram różnej wielkości jednocześnie

Druk cyfrowy

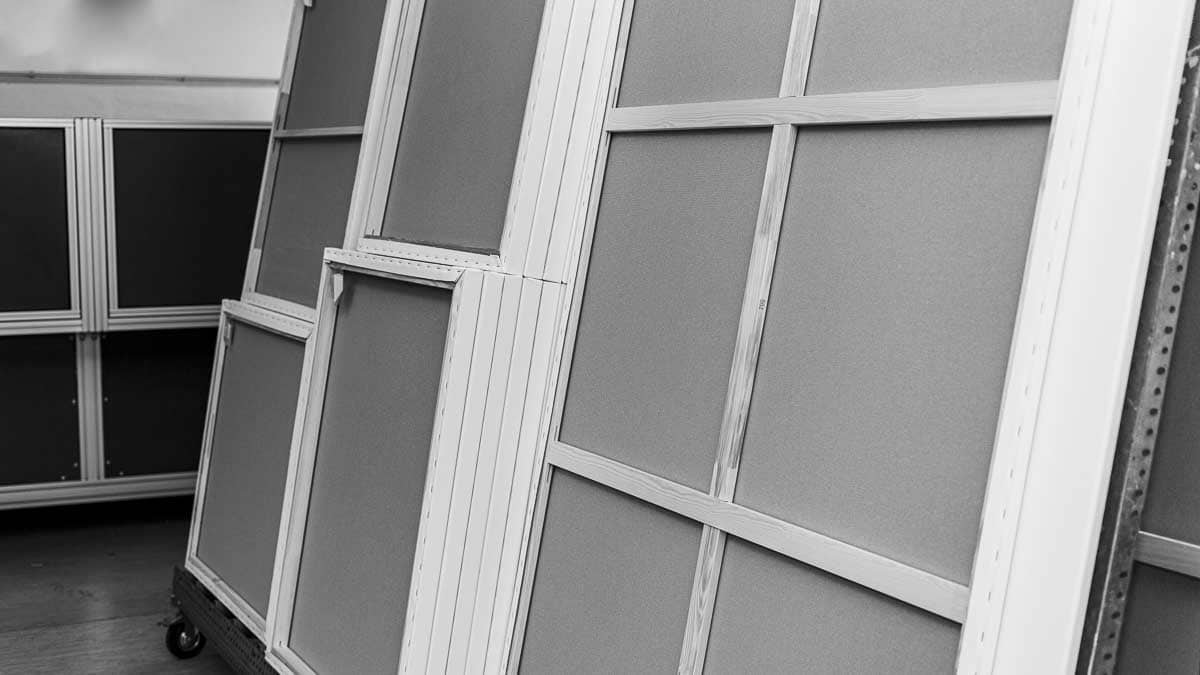

Czy to len, czy tkanina z nadrukiem, MHP SpeedF napina płótno na ramy zawsze z perfekcyjną jakością

Generacja 5

- Zdalny serwis i wirtualna diagnostyka

- Eksport danych i statystyk

- Optymalizacja produkcji multilength

- Nowoczesny wyświetlacz z nowymi funkcjami

MHP SpeedF L – WIĘKSZA PRODUKCJA

MHP SpeedF X – RAMY XXL

Bardzo duże ramy

Dzięki bardzo dużemu blatowi roboczemu MHP SpeedF X może przygotowywać płótna o formacie XXL. Możliwe są ciągłe zmiany formatu od 30 x 30 cm do 200 x 200 cm.

Materiał

Tak jak wszystkie maszyny naciągające MHP, MHP SpeedF X również obsługuje najróżniejsze materiały. Wchodzą tu w grę tkanina z nadrukiem, len lub nieprzetworzony materiał.