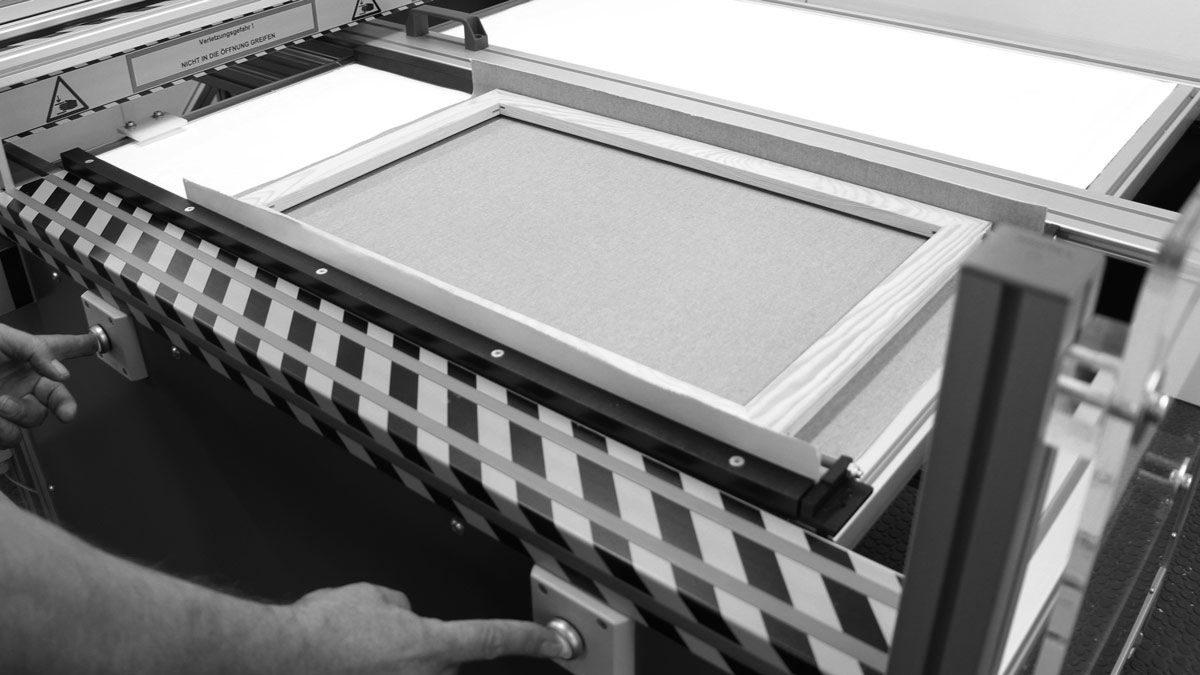

IT´S TIME TO AUTOMATE!

MHP Technology is your partner for canvas stretching machines | Stretch and frame assembly | Frame. We develop technology that simply works for producers. Whether digital prints or artist canvas: MHP machines provide flexibility in the production, maximum operations efficiency, and highest-quality product. Our technology truly stretches canvas for perfect, drum-tight quality. Benefit from our expertise from over 30 years of manufacturing experience.

UPCOMING DATES

April 24, 2024 | IGEPA Lounge | Dieburg, Germany

May 28 – June 7, 2024 | drupa | Düsseldorf, Germany | contact us to meet

September 10-12, 2024 | Printing United Expo | Las Vegas, USA | Booth C306